Efficiency from the first plate to the last

HOW TO OPTIMIZE YOUR WAREHOUSE

Many warehouses are poorly organized — materials are stored on the floor or stacked randomly on pallets. This causes frustration, costs time and leads to bottlenecks in the supply chain.

The solution? Optimize the warehouse smartly! Your employees will always have an overview, costly production delays will be a thing of the past, and your efficiency will increase noticeably.

Warehouse optimization made easy

5 tips for an optimized warehouse

A well-stocked warehouse is the heart of every company and the foundation for business success. We would therefore like to share with you five tried-and-tested tips that will help you optimize your warehouse and increase your sales.

Conduct thorough demand analyses at regular intervals to understand which products are most in demand.

Organize your products so that frequently requested items are easily accessible and storage space is not wasted

Integrate warehouse management systems and automated storage solutions to improve the accuracy and efficiency of your warehouse processes

Define clear process flows for receiving, putaway, picking, and shipping.

Track warehouse metrics such as inventory turns and storage costs to evaluate your efficiency and identify areas for improvement.

Practical and space-saving

With the right shelving to an optimized warehouse

A well thought-out warehouse design and sorted storage are crucial for optimizing your warehouse. The shelving systems you choose play a decisive role in this. Depending on the type and size of the stored products as well as the individual requirements of your company, different types of shelving can be useful.

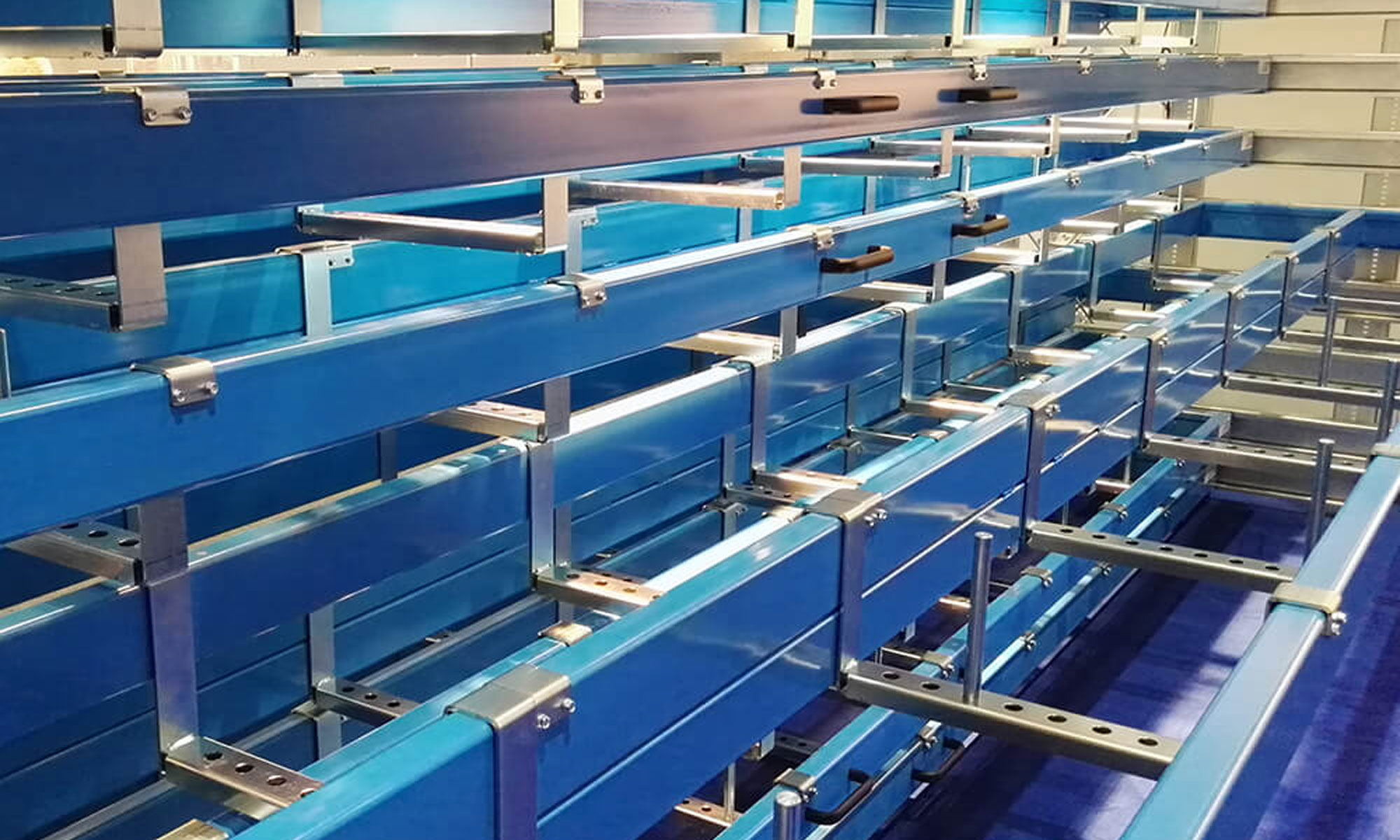

- Cassette racks: enable the clear storage of long goods such as tubes, sheets, profiles & rods

- Drawer racks: are used to protect products from material damage and are therefore also well suited for the storage of pipes, profiles and metal sheets

- Heavy duty racks: are ideal for bulky materials and large products with high weight such as machine parts and heavy tools

- Pallet racks: offer a space-saving solution for storing palletized goods in cartons and other packaging units

- Flow racks: are best suited for storing materials where quick access is needed

The targeted selection and arrangement of racking systems not only allows you to make the best use of available space, but also significantly increases the efficiency of your storage processes.

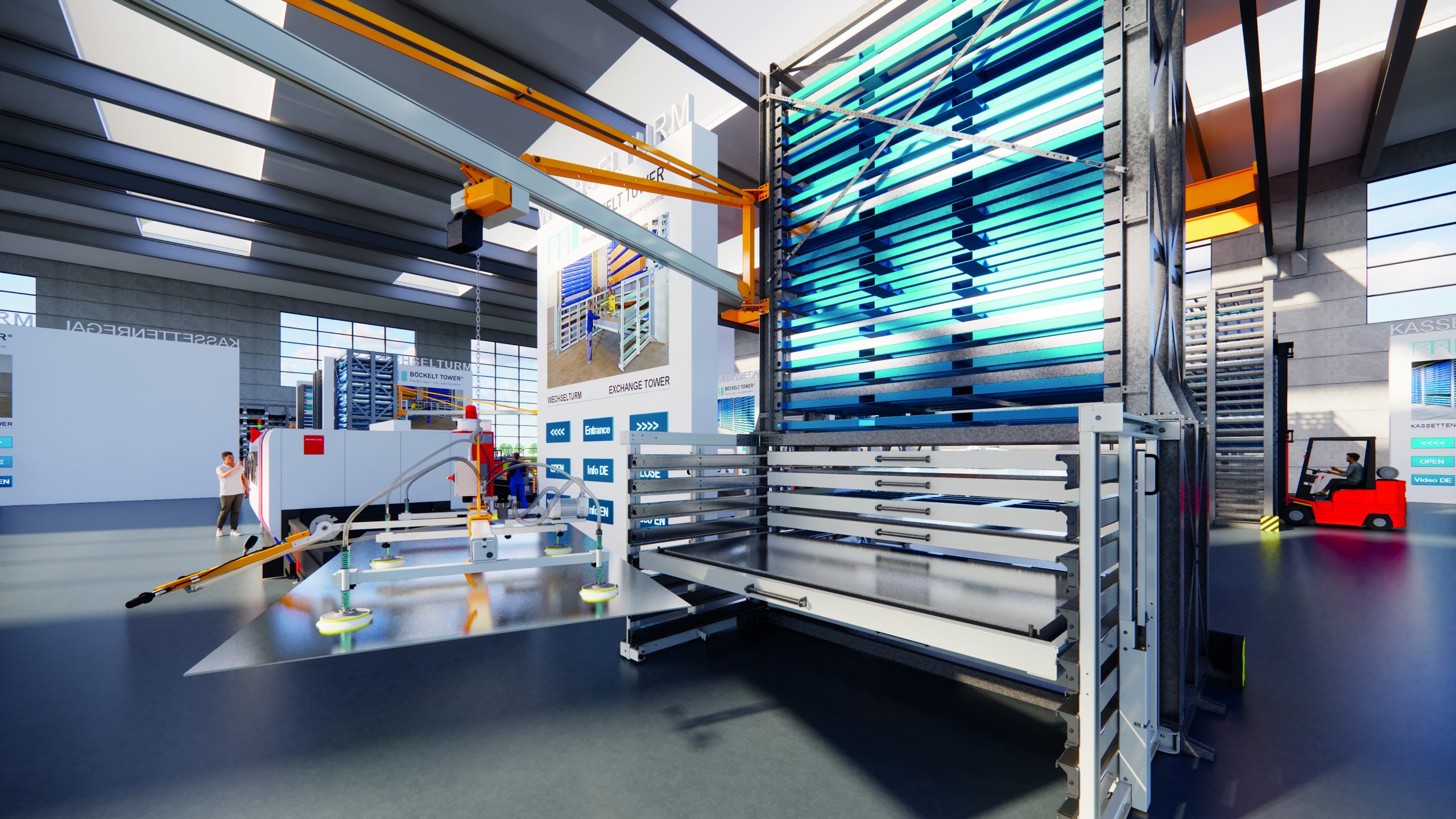

Optimizing bearings with the smart Böckelt solution

Structure that is reflected in every sheet

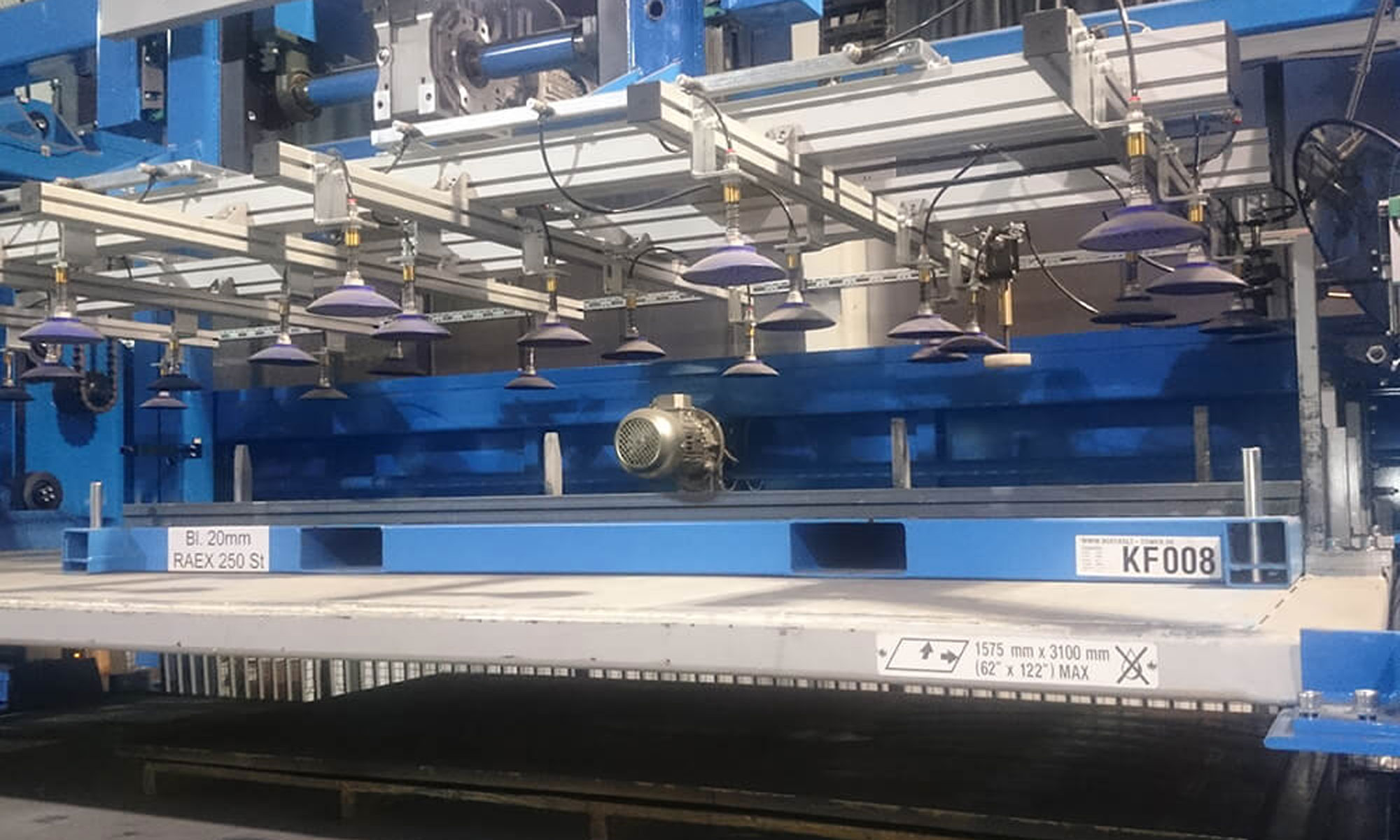

If adaptability is important to you and you want to optimize your warehouse, you should rely on the Böckelt shuttle tower. Our modular sheet metal storage tower is optimally designed to increase your productivity. For example, it consists of a drawer rack, which can be supplemented with a cassette rack if required. With an integrated slewing crane and vacuum lifter, it is also perfectly equipped to provide sheet metal for various processing machines. Operate:

• Laser cutting machines

• Gantry cutting machines

• Punching or shearing

Optimize warehouse & logistics

SHEET METAL STORAGE WITH A SYSTEM

By implementing a user-friendly storage system, it is possible to track the current location of your materials in real time. This optimizes the logistics in your warehouse and allows your staff to get back to more important problems than the tedious search for materials.

Optimize bearings — why at all?

Because structure creates space for success

Minimize accident risks

Safety First also applies to warehouse optimization

Optimizing warehouses not only means making the best possible use of space, but also creating a working environment that meets the highest safety standards. Especially in sheet metal storage, there is otherwise a great risk of injury. In addition to innovative storage solutions, you should therefore also attach great importance to suitable protective measures. This makes the sheet metal storage facility a place where top performance and safety go hand in hand.

Relief through order

Optimize logistics & minimize training times

Driving a forklift and transporting goods from A to B is easy to learn. Not so! Particularly in larger warehouses, employees often have to go through lengthy training and elaborate familiarization phases in order to fully understand the prevailing system and keep the internal logistics processes running efficiently.

With an optimized warehouse, you can:

• reduce this familiarization period: Deploy employees more quickly on their own

• Increase your efficiency: reduce errors & make the best use of resources

• Relieve employees: avoid time-consuming material searches & inventory checks

• Increase job satisfaction: make everyday tasks effortless & stress-free

Maximum efficiency, minimum waste

Sheet by sheet to the optimized warehouse

Remnants can be found in every warehouse — optimized or not. Whether they inevitably cause problems such as wasted resources or great chaos, however, depends to a large extent on how they are handled. If, for example, they are deposited in the remotest depths of the warehouse without being labeled and without a system, they will inevitably be forgotten. If, on the other hand, they are carelessly placed wherever there is room, dangerous trip hazards are created and there is a risk of material damage.

Systematic success

OPTIMIZE LOGISTICS & COLLECT BENEFITS

A lack of overview can not only cause difficulties in physical storage, but can also trigger conflicts in terms of software. With the help of an optimized warehouse and our intelligent management system, you can therefore easily:

Optimize warehouse & keep the overview

From warehouse chaos to clear traceability

Always knowing where something is and when — the dream of every warehouse manager. In reality, however, it is difficult to realize this dream:

• Sheets get lost and remain missing

• Remaining stock suddenly appears or disappears

• urgently needed materials cannot be found

The traceability of sheet metal is extremely important in order to be able to act quickly in the event of quality defects or recalls. It is therefore essential to optimize the warehouse with an intelligent warehouse management system in order to meet this requirement.

More overview less effort

Optimize warehouse & simplify tracking

Our intelligent warehouse management system allows you to track your inventory in real time. This allows you to see exactly where which product is at the current time. Seamless integration with existing applications such as enterprise resource planning or ERP systems also makes all relevant data centrally accessible.

Sustainably optimise logistics

rely on a growing system

Compared to permanently installed shelving, our modular storage systems offer an extremely cost-effective storage solution that can be adapted to changing needs at any time. Best of all, thanks to the ability to stack shelves flexibly in height, vertical space can be optimally utilized:

Benefit from:

• Space savings: utilize limited space & maximize storage capacity

• Cost savings: adapt as needed, without expensive rebuilds

• Labor savings: clearly visible shelf markings speed up your processes

More time for the essentials

Let experts optimize your warehouse

Create order, gain transparency

You want to optimize your warehouse? Here you will find all the information you need!

It’s important to us that you get the most out of your warehouse. So feel free to contact us if you have a specific question that is not answered here.

No, fortunately a complete restructuring of your existing warehouse is not necessary. Our warehouse solutions are designed to fit seamlessly into your existing systems.

There are a number of benefits to implementing warehouse management software. For example, it automates warehouse processes, provides real-time visibility into inventory levels, and makes it easier for you to take stock. Furthermore, it can speed up order processing, which automatically reduces storage costs.

Yes, our racks can be conveniently and safely loaded and unloaded using ordinary forklifts.

Haven’t found an answer yet? Feel free to call us: