No more idling

How to optimize your set-up times

Machine downtimes, waiting employees and bottlenecks in the supply chain are the horror of every entrepreneur. These scenarios not only disrupt the workflow, but also lead to financial losses and dissatisfied customers in the long term. How can you avoid this?

By optimizing your set-up times: With a well thought-out storage system, for example. Once materials and components are easily accessible and well sorted, bottlenecks are identified at an early stage and the production flow is accelerated.

Production processes explained

What are set-up and non-productive times in production?

Production employees spend a large part of their daily working time searching for materials and maintaining machines. Secondary activities such as clamping, changing and refilling tools also take up valuable time. Time that, from an overall economic perspective, could be used much more efficiently elsewhere.

When it comes to optimizing production processes, the terms set-up time, idle time, throughput time and so on are often used in this context. We take a closer look at these terms for you and explain what these time spans are all about:

is required to change over a machine, system or production line to the production of a new component or order

the time during which a machine or system is at a standstill, for example due to maintenance, repairs or malfunctions

refers to the time that elapses during the complete manufacturing process of a product

for ancillary activities that do not directly contribute to the fulfillment of work tasks

is the sum of all process times, including set-up, auxiliary and throughput times

Ensure production flow

Optimized set-up times = Minimized non-productive times

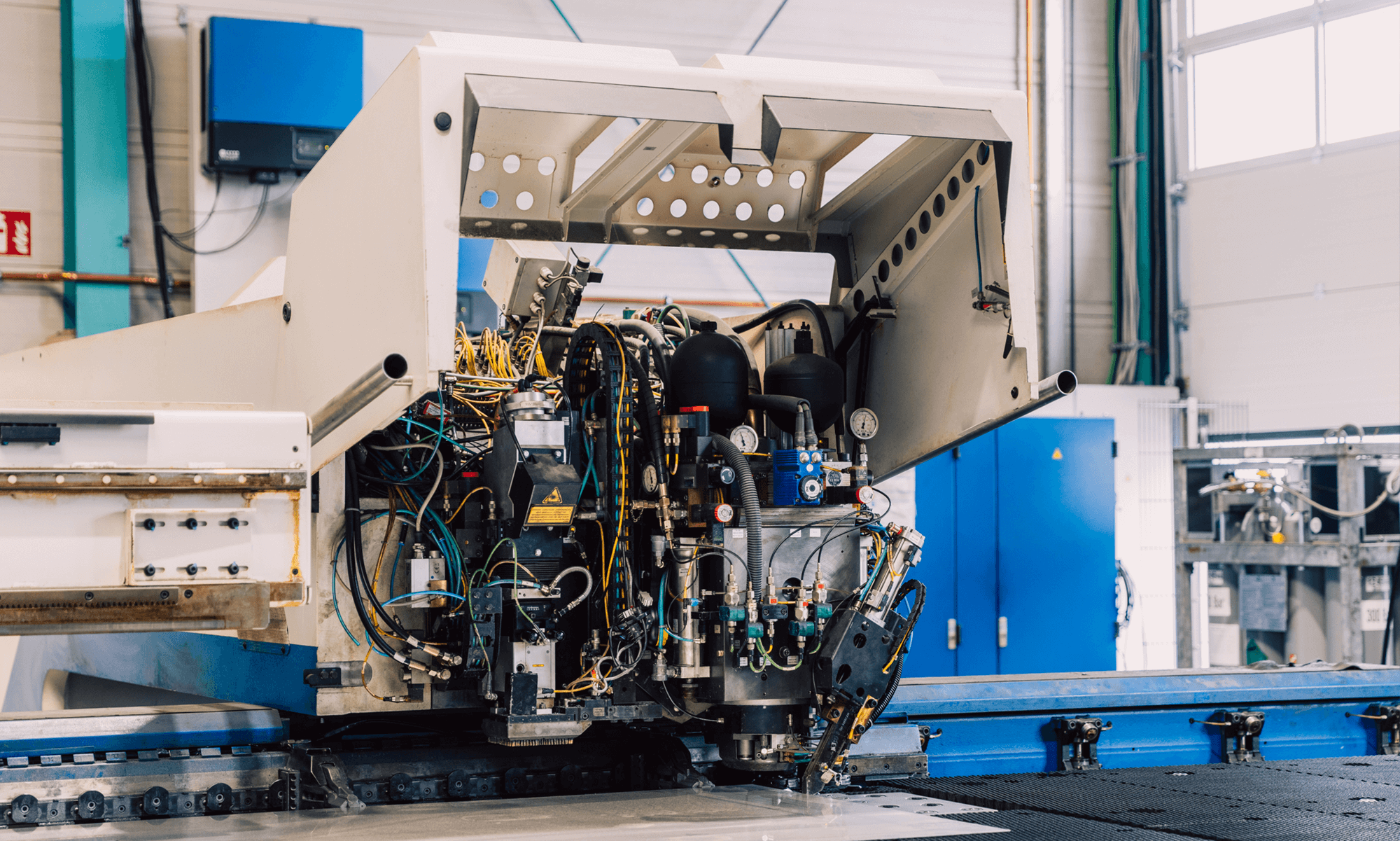

The same machine is often used to manufacture a wide variety of products, which means that individual tool components and settings have to be changed or adjusted regularly. These processes can sometimes be very time-consuming and result in long non-productive times. More efficient set-up processes can significantly shorten them, meaning that machines are ready for use more quickly and less time is wasted. Optimized set-up times are therefore the key to minimizing non-productive times in production.

Set-up times include:

- Switching production off and on again

- Cleaning the machines/equipment

- Setting up new tools/components

- Test runs, functional checks and quality assurance

Your competition is already optimizing

Reduce non-productive times and relieve production

In a study on process optimization in manufacturing, around 100 representatives of the metal and electrical industry were asked whether and, if so, to what extent they are already optimizing their setup times. The result was that non-productive times have long been a hot topic of discussion within the industry and are becoming increasingly important for production.

times a week, machines are usually retooled

a conversion takes hours on average

percent of respondents have already taken measures for optimization

percent is the potential for optimization

How modern manufacturing works

Optimize set-up times and collect benefits

Investing in the optimization of set-up times pays off in many ways in the long term. Here are just a few of the many benefits:

Non-productive times? Not with us!

We help you to optimize your set-up times

Methods presented

Optimizing set-up times for production at full speed

The targeted optimization of set-up times is therefore an essential step towards increasing efficiency in production. This opens up a wide range of starting points. Outstanding measures can be found in the area of lean management, for example. This management philosophy aims to reduce waste and improve the value chain. For example, there are special methods to reduce the time required for tool changes:

SMED

(Single Minute Exchange of Die)

SMED is a process that aims to make tool changes as efficient as possible. To this end, tasks are parallelized where possible, superfluous steps are eliminated and processes are standardized. A basic distinction is made between internal and external set-up steps.

- Internal set-up times: Time required during machine downtimes to carry out setups

- External setup times: Time required to prepare setups while the machines are still running

Once all setup steps have been identified and divided into internal and external activities, these can be optimized with the right warehouse equipment. In a sheet metal processing company, optimizing the warehouse could look something like this:

- Internal set-up times: such as the time required to feed the right materials to laser machines, cutting systems and the like can be reduced to an absolute minimum with our Böckelt shuttle tower with integrated slewing crane and vacuum lifter, for example

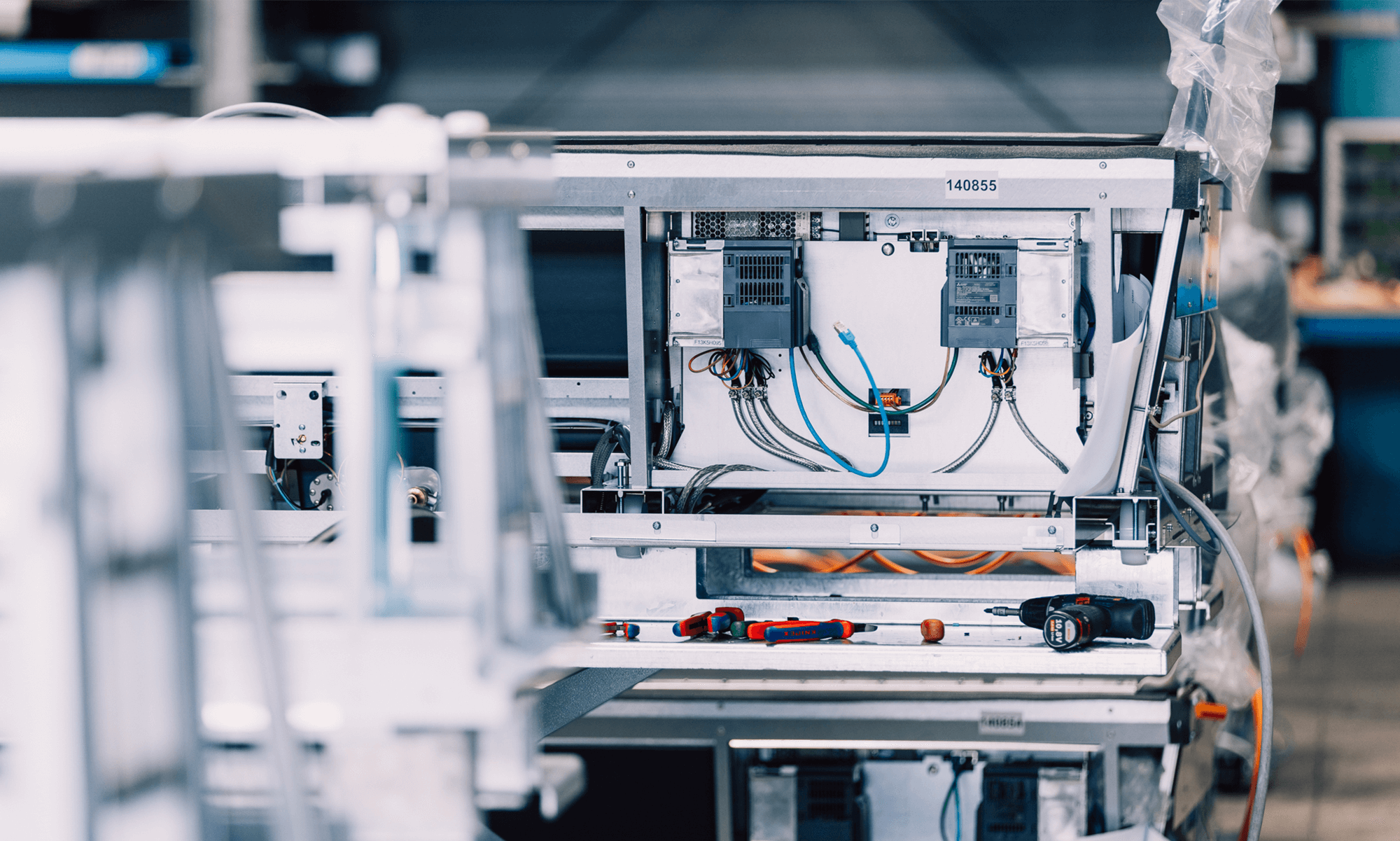

- External set-up times: can be reduced by using warehouse management software with a connected transponder system and starting the preparation of the next batch while production is still running

QCO (Quick Change Over)

Quick Change Over, or “quick set-up”, refers to switching quickly from the production of one product to the manufacture of another. You can do this particularly well by:

- develop standardized work instructions for each setup step

- make use of quick-change systems for your tools

- avoid long searches for materials with a well thought-out storage system

- keep an eye on your stock levels with intelligent management software

OTED (One-touch Exchange of Die)

OTED is a further development of SMED, in which the tool change takes place in a single work step or in less than a minute. A well-known example of a successful implementation is the tire change in Formula 1 racing. In the sheet metal processing industry, the realization of OTED is often difficult and cannot usually be implemented without specially developed machines. Moreover, even the best machines are useless if you do not have an optimized warehouse. We will be happy to advise you on your options.

Measures at a glance

Optimizing set-up times, where to start?

Starting without a plan is rarely a good idea — and optimizing set-up and non-productive times in production is no exception. We have therefore put together a selection of useful optimization measures for you:

Warehouse management systems (WMS) and automated storage solutions can help to efficiently track inventory, improve accuracy and ensure the availability of materials.

Quick-change systems and devices such as the slewing crane or vacuum lifter of our exchange tower can also help to minimize your set-up times.

Clear categorization of stock and shelves makes it easier to identify and select the required materials and minimizes the time spent searching for specific parts.

Regular stock checks help to avoid overstocking while ensuring that there is always enough material available to maintain production.

It makes sense to order materials so that they arrive exactly when they are needed for production. Our warehouse management software helps you to keep track of your stocks at all times and identify bottlenecks at an early stage.

The ability to trace materials back to their origin is important in order to quickly identify and sort out faulty or problematic parts. Here too, our warehouse management system can provide valuable services.

Well-trained employees understand warehouse organization, know how to search and store efficiently and can thus help to speed up your processes.

Haven’t found the right answer yet? Give us a quick call and let’s chat!

No time to stand still

We support you in optimizing your set-up times